How To Repair A 6.5 Horsepower Briggs And Stratton Mower

How do I troubleshoot & repair common small engine bug?

Having engine problems? Utilise this comprehensive guide when troubleshooting problems with your lawn mower, snowfall blower or other outdoor ability products - whether your product won't start, is stalling, surging or running rough.

Lawn Mower / Equipment Engine Won't Commencement

Pocket-size Engine Runs Poorly

Maintenance & Repair Schedule

![]() Alert: Always read the engine and equipment manual(s) earlier starting, operating, or servicing your engine or equipment to avert personal injury or property damage. See an authorized dealer or contact Briggs & Stratton if yous are unsure of any procedure or have additional questions. Find all Engine Condom Warnings

Alert: Always read the engine and equipment manual(s) earlier starting, operating, or servicing your engine or equipment to avert personal injury or property damage. See an authorized dealer or contact Briggs & Stratton if yous are unsure of any procedure or have additional questions. Find all Engine Condom Warnings

Lawn Mower / Equipment Engine Won't Kickoff

Engine starting issues accept a few mutual causes, specially if yous're using your lawn mower or outdoor ability production after information technology's been stored for the winter or off-season.

Condom Tip: ALWAYS remove / disconnect the spark plug before performing engine repair.

Stride ane: Bank check Your Fuel

Do y'all have fresh, clean fuel in the tank? If it's empty, fill it upwards and become! If information technology's total, cheque that the fuel close-off valve is open up and that it is clean.

Dried fuel, dirt and debris are the most common cause of outdoor power equipment not starting properly. If you store equipment with untreated gas in the tank, it can atomic number 82 to engine damage.

Forbid this problem in accelerate through proper lawn mower & outdoor power equipment storage. Using fuel stabilizer will go on your gas from creating small engine problems.

Step 2: Clean the Carburetor

Carburetor Problems Cause Mower Engines Not To StartThe carburetor regulates how air and fuel motion through the engine to ability your equipment. If it is dirty, that can crusade poor engine performance or starting bug.

>> Follow these steps for cleaning carburetors

>> Follow these steps for carburetor rebuild

Step 3: Cheque the Spark Plug & Possible Ignition Bug

Disconnected, dirty or fouled spark plugs are common causes for engines that won't start. Spark plugs typically need to exist replaced every season or 25 hours of use. You should also check that the spark plug gap is prepare properly.

>> Follow this guide on checking and replacing spark plugs

If your spark plugs look good, issues with your ignition system tin also preventing a spark. These can range from a faulty spark plug pb, shorted impale switch or flywheel key damage.

To test and set, check out our Modest Engine Ignition Systems FAQ or reach out to your local Briggs & Stratton dealer for avant-garde repair help.

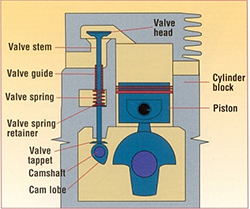

Step 4: Bank check the Valves & Compression System

Air-fuel compression is crucial to engines powering lawn mowers and outdoor power equipment. The compressions organization is made up of valves, piston, cylinders and rings that control how the air and fuel vapors move through the engine. Valves let air in (the intake valve) and out (the exhaust valve), pistons move back and along pushing the air-fuel mixture to the ignition system and the piston rings go on it all sealed up tight.

If in that location isn't proper valve clearance or there's a leak, this can cause compression problems that keep an engine from starting. You can perform a pinch organisation with a leak down tester. If you don't take one of these, we recommend visiting your Briggs & Stratton repair dealer to perform the test and check that these components are in good shape.

Small Engine Runs Poorly

Use this simple Q&A format list to troubleshoot minor engine problems you may feel with your backyard mower, snow blower or other power equipment.

Engine Stalling, Surging or Running Crude

When your engine starts and stalls, it is often due to standard maintenance problems. Forbid stalling issues before they start with a tune-up kit. See "Why My Engine Won't Start" section above or utilize the Q&A guide below.

Is your fuel fresh?

Stale, untreated gas begins to intermission downward after about a month. Bleed the gas from your backyard mower our outdoor power equipment, then supplant with fresh gas and fuel stabilizer to extend the life of your fuel.

Is the air filter dirty / plugged?

Clean or replace the air filter.

Is the spark plug fouled?

Clean spark plugs where applicative (Follow instructions for checking and changing spark plugs).

Is your oil fresh?

Check your oil level and advent every time yous use your engine while it is cold. Your oil needs to be inverse every 25 hours of use or season. (See Checking and Changing Mower Oil)

Engines Smoking

Is the engine emitting white / blue smoke?

This ways your engine called-for oil. (run into Engine emits white/blueish fume while running).

Is the engine emitting black fume?

You demand to perform a Carburetor Adjustment.

Is the air filter dirty / plugged?

Clean or replace the air filter.

Engine Overheating

Is the engine dirty?

Follow instructions for safely cleaning & removing debris from small engines.

Is the oil level depression?

Add oil to the engine. NOTE: Never add oil to the gasoline for a four-stroke engine (see Checking & Irresolute Oil).

Are any shrouds or cooling fins missing or broken?

Install new parts every bit needed. Reference your repair manual, available for purchase.

Is the fuel mixture too lean?

You can determine if your air-fuel mixture is off past checking the state of your carburetor. Use this Carburetor Adjustment FAQ as a guide.

Is there a leaky gasket?

This is another mutual carburetor problem associated with overheating engines. Larn how to check and supervene upon the gasket (run across Backyard Mower Carburetor Rebuild FAQ).

Is the fuel tank vent or fuel tank screen plugged?

Make clean the fuel tank vent and screen.

Engine Knocking

Does the combustion chamber contain excess carbon?

Carbon deposits can form on your combustion chamber. If you run across any, just clean carbon from the piston and caput (see Removing Engine Carbon Deposits).

Is the flywheel loose?

Inspect the flywheel and key; supercede as needed (run across Inspecting the Flywheel & Key).

Is the spark plug lead faulty?

Test the atomic number 82 with a spark tester, so test the engine (encounter Servicing Spark Plugs).

Spark Plug Fails When In Utilise

Is the spark plug fouled?

Clean spark plugs where applicable (Follow instructions for checking & changing spark plugs).

Is the spark plug faulty or gap wrong?

Replace the spark plug or accommodate the spark plug gap (see Spark Plug Gap FAQ).

Are the breaker points faulty?

Check the ignition systems' breaker points. If they are faulty, install a solid-land ignition (run across Troubleshooting Ignition Bug).

Are your carburetor settings correct?

Bank check your modest engine's carburetor settings. Find the proper carburetor settings and step-by-step directions for Carburetor Aligning.

Is the valve leap weak?

Check that the valve jump still has tension.

To access this, y'all'll have to remove the muffler, crankcase and other components blocking the valve chamber. Then, remove the cylinder head bolts (label for easy re-installation)

Suit the jaws of the valve leap compressor until they touch the superlative and lesser of the valve chamber

Push the tool in to compress the spring and tighten the jaws

Remove the retainers and lift out the valves , compressors and springs

If you lot discover weak springs, replace them based on your small engine's specifications. These can be establish in your operator'southward manual.

Is the valve clearance set incorrectly?

If your valve bound is still working well, check the clearance. Valves that stick or have leaks tin can cause an engine to terminate running. Adjust the valve clearance to recommended settings (run across your operator's manual).

Source: https://www.briggsandstratton.com/eu/en_gb/support/faqs/browse/engine-problem-solving-tips.html

Posted by: chessrowas1986.blogspot.com

0 Response to "How To Repair A 6.5 Horsepower Briggs And Stratton Mower"

Post a Comment